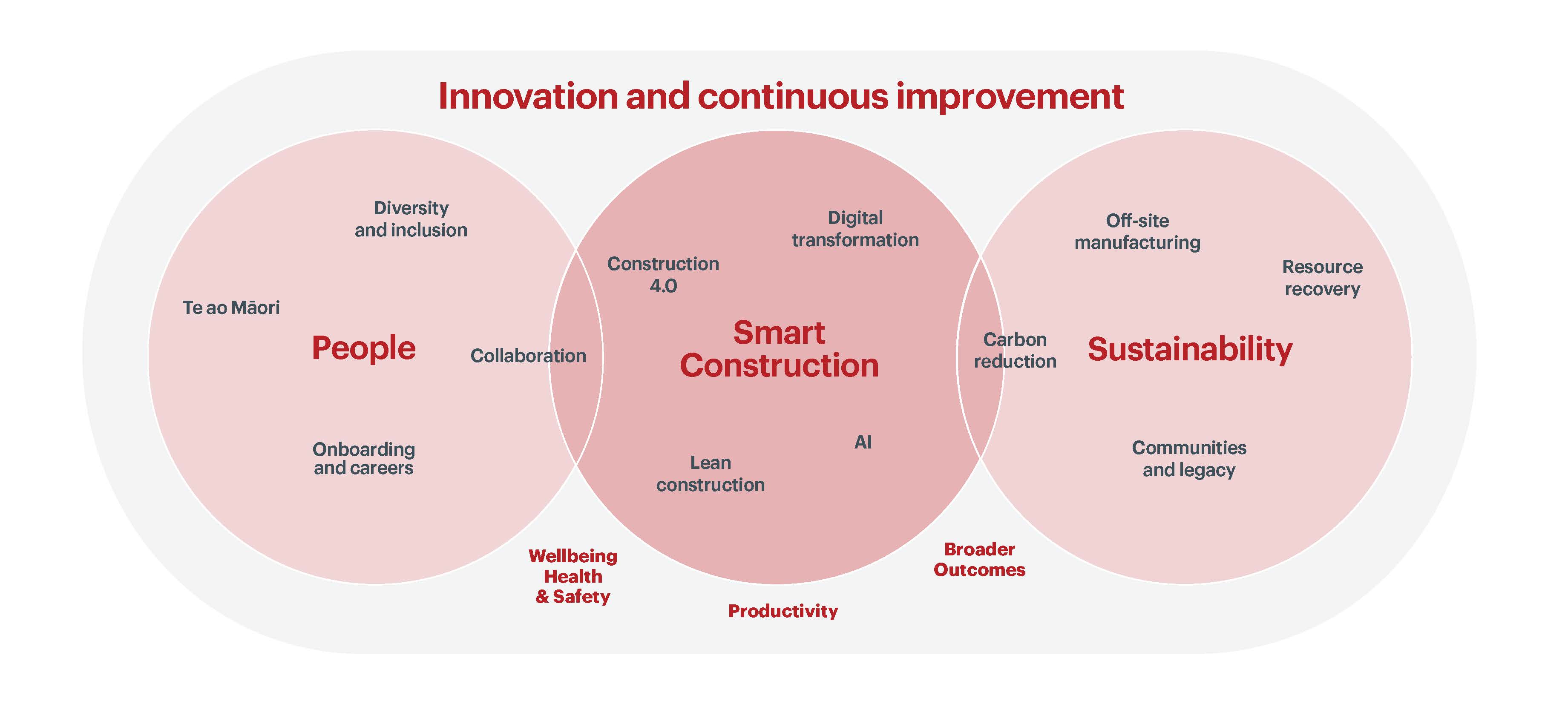

We take our role as a leader in the construction sector seriously.

We encourage our teams to use innovative approaches to solve issues and explore opportunities.

In the spirit of collaboration, we want to share this information with all construction professionals, experts, academia and thought leaders for the good of the wider industry.

We value the strength of collaboration and partnering in addressing the many interconnected opportunity areas for our sector.

To that end we want to promote and share the great work of partner organisations in these areas.

To view these stories, please share your details so we can send information that might be of interest and invite you to thought leadership events.

If you would like to learn more, or have information you’d like to share with the wider industry – contact the team here.

Senior Site Engineer Clifford Dsouza talks about the BPC Foundations team’s efforts to prevent further erosion of a cliff that collapsed during Cyclone Gabrielle.

Senior Site Engineer Clifford Dsouza talks about the BPC Foundations team’s efforts to prevent further erosion of a cliff that collapsed during Cyclone Gabrielle. The project was made very complex due to the incredibly restricted site that remained after the major slip. This was originally a Design Community of Practise quickfire presentation.

National Survey Manager Nebojsa Ludajic explains how he’s been surveying manholes using laser scanning technology.

National Survey Manager Nebojsa Ludajic explains how he’s been surveying manholes using laser scanning technology. This approach provides significant improvements in safety and data collection. This was originally a Design Community of Practise quickfire presentation.

Anglian Water is a world leader in reducing carbon emissions.

Anglian Water is a world leader in reducing carbon emissions. As an early starter, the big UK water utility embarked on its carbon zero journey in 2006 and is now on track to generate 45 percent of energy from its own renewable resources by 2025 and become a full net zero carbon business by 2030.

In this Spotify podcast Jon Reed and Hannah Edmond from the Water New Zealand climate change group talk to Anglian Water’s head of carbon neutrality, David Riley about the water utility’s bold approach to tackling climate change and the carbon reduction lens covering all aspects of its operation.

Click here to go to the podcast.

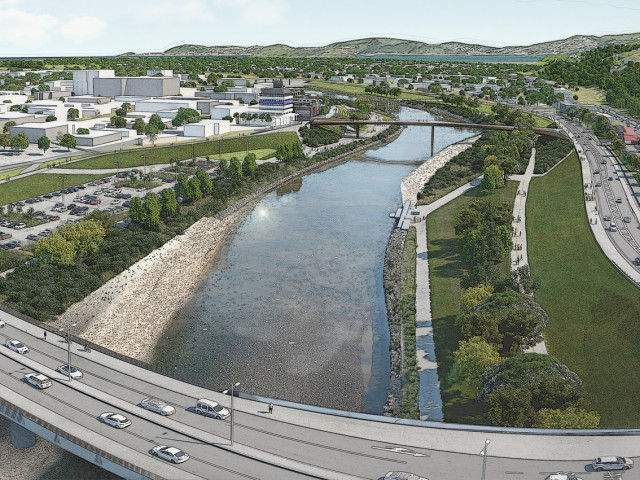

The City Rail Link (CRL) is being designed and constructed to the highest sustainability standards.

The City Rail Link (CRL) is being designed and constructed to the highest sustainability standards.

The CRL project aims to achieve sustainability excellence by being careful with the resources it uses, optimising its carbon footprint, avoiding waste and leaving a positive social and cultural legacy for Tāmaki Makaurau.

Visit the City Rail Link website

Brian Perry Civil's Seaview Wharf Resilience Project construction manager and environmental and sustainability advisor joined the Lunch and Learn session to talk about the ecological and environmental...

Brian Perry Civil's Seaview Wharf Resilience Project construction manager and environmental and sustainability advisor joined the Lunch and Learn session to talk about the ecological and environmental considerations working in Centre Point, Wellington.

Our Brian Perry Civil team share lessons learned from the Helensville wastewater treatment upgrade in this Lunch and Learn session.

Our Brian Perry Civil team share lessons learned from the Helensville wastewater treatment upgrade in this Lunch and Learn session.

ViDoc is the combination of the iPhone Lidar scanning and a GPS antenna mounted on the phone cover.

ViDoc is the combination of the iPhone Lidar scanning and a GPS antenna mounted on the phone cover. This allows us to scan our work and georeference the scans with high accuracy.

We’re using ‘Innovation Sprints’ to help solve business challenges and accelerate innovative ideas.

We’re using ‘Innovation Sprints’ to help solve business challenges and accelerate innovative ideas. The sprints help us to quickly come up with the right solutions in a short time.

Working together, our Operational and Environment, Health and Safety group recently took this Agile approach to help keep our people safe. They organised a sprint focused on finding an engineering solution to manage the critical risk of our people being struck by mobile plant such as excavators, rollers, cranes, etc.

In just six weeks the team scanned the globe and came up with a solution which complements our Safe Work System for People Interface Zones – installing AI cameras on plant blind spots to clearly identify and locate people who inadvertently enter into a blind spot on an operational piece of plant so the operator can take appropriate action to prevent a potential harm event.

This solution has been installed on a variety of machines and sites where the risk is the highest, with more to come!

Subsidised staff transport on AT services make public transport the easy choice.

Subsidised staff transport on AT services make public transport the easy choice.

Fareshare allows employers to offer subsidised public transport to staff, on AT services, as an employee benefit which is exempt from fringe benefit tax. Subsidise either 25%, 50% or 75%, on weekdays only or 7-days.

Email to find out more: fareshare@at.govt.nz

About Fareshare

Opportunities exist with Firth to save water by increasing recycled water in concrete mixes.

Opportunities exist with Firth to save water by increasing recycled water in concrete mixes.

Reducing construction waste can be easier than you think.

Reducing construction waste can be easier than you think. Making small changes to things you already do can make a massive difference.

Visit the Master Builders website

Keep Britain Tidy today unveils a newly designed and tested version of the waste hierarchy as part of fresh guidance to help the industry to better educate the public about waste prevention and mindfu...

Keep Britain Tidy today unveils a newly designed and tested version of the waste hierarchy as part of fresh guidance to help the industry to better educate the public about waste prevention and mindful consumption and urgently accelerate the UK’s transition to a circular economy.

Visit the Keep Britain Tidy website

Carbon management and reporting help us understand industry challenges and develop solutions aligning to net zero carbon transition and positive environmental outcomes.

Carbon management and reporting help us understand industry challenges and develop solutions aligning to net zero carbon transition and positive environmental outcomes.

The Brian Perry Civil (BPC) team managing the construction of Silverstream Pipe Bridge – replacing the Wellington region’s most critical water supply asset and supplying all water to Porirua City and North Wellington – used the ECI process to reduce carbon on the project by 62%. This was achieved through collaborative design changes alongside Wellington Water and designer Holmes that reduced the both quantity and type of materials used.

Fletcher Construction's Critical Bridges Project construction manager shares the team's five-year journey constructing bridges in Fiji in this Lunch and Learn session.

Fletcher Construction's Critical Bridges Project construction manager shares the team's five-year journey constructing bridges in Fiji in this Lunch and Learn session.

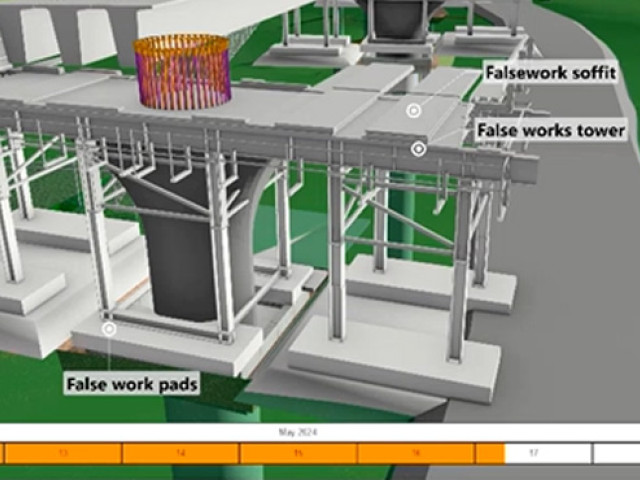

The question has been asked several times about digital engineering in infrastructure and how we get value from putting our time and energy to enabling digital engineering practices.

The question has been asked several times about digital engineering in infrastructure and how we get value from putting our time and energy to enabling digital engineering practices. This Lunch and Learn sessions aims to articulate what digital engineering is.

In a sprint organised by Fletcher Construction, the Eastern Busway project team looked at buried services as a key risk and came up with how to do things better.

In a sprint organised by Fletcher Construction, the Eastern Busway project team looked at buried services as a key risk and came up with how to do things better. Find out how they did it in this Lunch and Learn session.

Resources for the promotion of Construction careers from across the NZ Infrastructure sector.

Resources for the promotion of Construction careers from across the NZ Infrastructure sector.

Visit the EPIC website

Design Community of Practise quickfire presentation: A presentation from our Delivery Outcomes Manager, Matt Findlay outlining the New Zealand Upgrade Programme (NZUP).

Design Community of Practise quickfire presentation: A presentation from our Delivery Outcomes Manager, Matt Findlay outlining the New Zealand Upgrade Programme (NZUP).

What's next for you?

Join us and we’ll get you all set for what’s next – from the career you want to the lifestyle you’re dreaming of. The size and scale of our operations means we can offer an impressive range of opportunities across the country.