We take our role as a leader in the construction sector seriously.

We encourage our teams to use innovative approaches to solve issues and explore opportunities.

In the spirit of collaboration, we want to share this information with all construction professionals, experts, academia and thought leaders for the good of the wider industry.

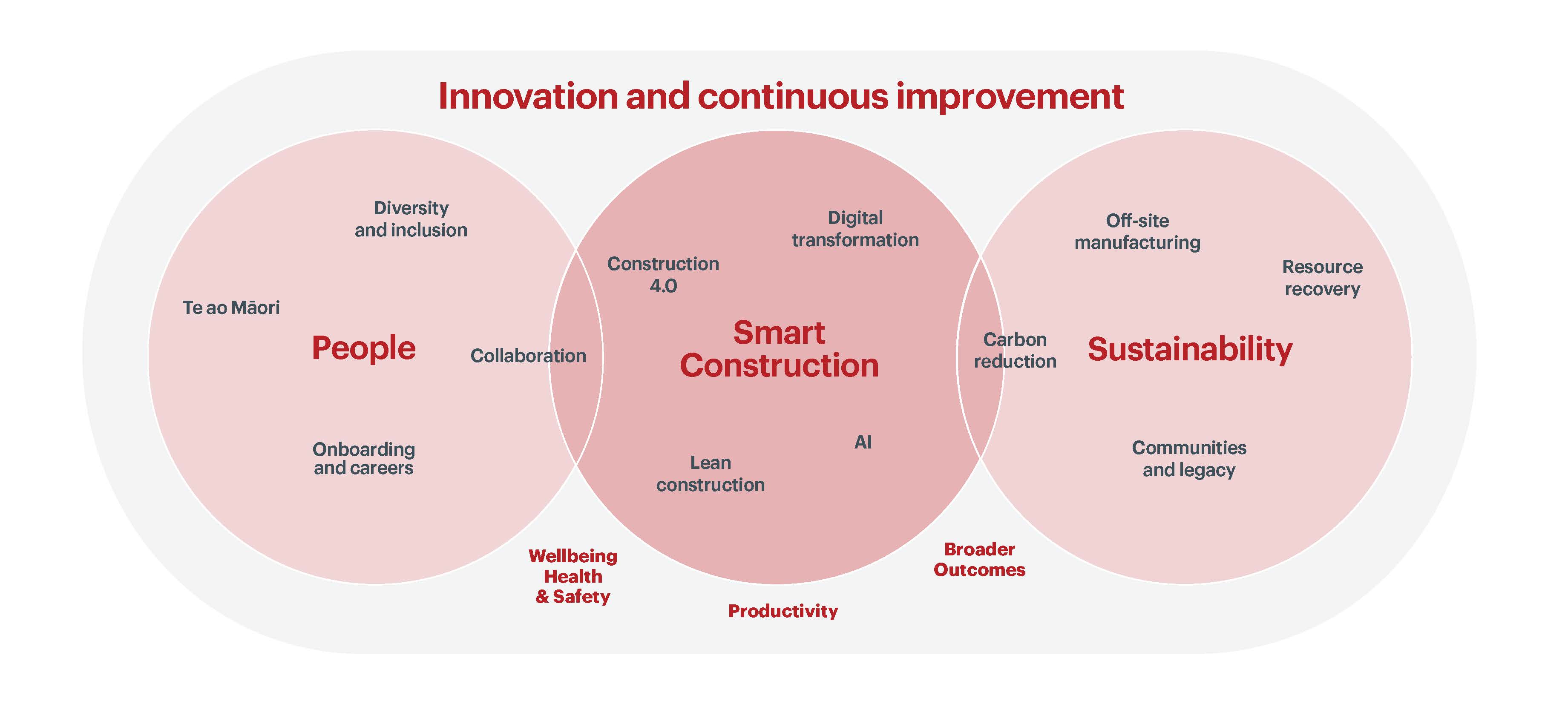

We value the strength of collaboration and partnering in addressing the many interconnected opportunity areas for our sector.

To that end we want to promote and share the great work of partner organisations in these areas.

To view these stories, please share your details so we can send information that might be of interest and invite you to thought leadership events.

If you would like to learn more, or have information you’d like to share with the wider industry – contact the team here.

BPC Site Superintendent Paddy Molloy recognised an opportunity to improve environmental practices by avoiding used safety glasses being sent to landfill.

BPC Site Superintendent Paddy Molloy recognised an opportunity to improve environmental practices by avoiding used safety glasses being sent to landfill.

Working with Project Administrator Sue Hodder at their Seaview Wharf site, they’re now ensuring an average of 70 pairs of glasses are being recycled each month.

They’re working with Terracycle, a company offering a range of recycling options for construction site waste. The next objective is to introduce recycling boxes for gloves and other personal protective items.

While it can be tempting to ‘ease’ into things at the start of the year, it is integral we hit the ground running with our safety mindset fully engaged so none of our people become one of the 'lucky o...

While it can be tempting to ‘ease’ into things at the start of the year, it is integral we hit the ground running with our safety mindset fully engaged so none of our people become one of the 'lucky ones'.

In this powerful story, hear from Brian Perry Civil's Mason Hohepa, in the Bay of Plenty, who shares his close call with a serious injury, and the valuable lessons he and his team learned about staying committed to safety-on-site.

Everyday, we live our values to care for each other, so we can all call go home safely and through our dedicated safety culture programme Protect, we have built a strong collective belief that all injuries are preventable.

Our Higgins Traffic team is leading a recycling initiative aimed at boosting sustainability and reducing costs.

Our Higgins Traffic team is leading a recycling initiative aimed at boosting sustainability and reducing costs.

The team, which relies heavily on traffic management, previously faced high expenses for aluminium traffic signs. Old and damaged signs were sent to scrap metal, yielding less than one-eighth of their original cost. Traffic Operations Manager Sanjesh Narayan reviewed the current process and explored the feasibility of reusing or refurbishing these signs. The findings revealed that recycling the signs was far more cost-effective than purchasing new ones.

This initiative resulted in significant savings for the division. Large signs were converted into multiple smaller ones at half the original cost, reducing expenses and increasing the inventory of usable signs. This recycling effort has made their operations more sustainable by reusing materials and cutting down on costs.

Safety is a core value and a core part of who we are.

Safety is a core value and a core part of who we are. We want to help create safer workplaces for everyone, everywhere. That’s why we’re sharing our safety journey online through a new safety section on the Fletcher Building website.

By openly sharing our learnings, progress, approach, and commitment, we’re working to ensure that everyone goes home safe, every day and contributing to a stronger safety culture across the industries and communities we work in.

We’d love to hear from others in the EHS space—how is your business driving safety excellence? Let’s keep the safety conversation going.

Click here to visit the page.

The Eighteenth East Asia-Pacific Conference on Structural Engineering and Construction (EASEC-18) was held on 13–15 November 2024 at the Shangri-La Chiang Mai in Thailand.

The Eighteenth East Asia-Pacific Conference on Structural Engineering and Construction (EASEC-18) was held on 13–15 November 2024 at the Shangri-La Chiang Mai in Thailand. The conference was hosted by the School of Civil Engineering and Technology, Sirindhorn International Institute of Technology, Thammasat University.

Fletcher Higgins Fiji Project Manager Tiago Ribeiro presented two technical papers - Bulu Bridge – Repairs and Overlay with Latex Modified Concrete Reinforced with Fibres, and Wainawi Bridge – 2 Stage Construction Methodology.

Facing the climate challenge demands leadership and collaboration across the entire industry.

Facing the climate challenge demands leadership and collaboration across the entire industry. At the recent Carbon Crunch event hosted by Mott MacDonald, Brian Perry Civil Environmental and Sustainability Manager Rachel Blake represented the construction sector, highlighting the tailwinds and crosswinds in the journey towards decarbonization. It was an informative and thought-provoking event that delved into the path forward and the crucial imperatives we must address together to eliminate carbon from our future.

Due to a lack in historical evidence and as-built records, service investigation is becoming increasingly more important.

Due to a lack in historical evidence and as-built records, service investigation is becoming increasingly more important.

Locating services during planning processes for projects can stop service strikes, costly conflicts, redesigns and unsafe environments for our workers, including in some cases loss of life.

In this Lunch and Learn session, Geospatial Technician Briana Stemp talks about GPR benefits and service locating processes.

Fletcher Reinforcing constructs the prefabricated flared reinforcing columns for piers on the flyover above Reeves Road on the Eastern Busway Project.

Fletcher Reinforcing constructs the prefabricated flared reinforcing columns for piers on the flyover above Reeves Road on the Eastern Busway Project.

The flyover is a major part of the project connecting the South-Eastern Highway with Pakūranga Road, reducing traffic on Pakūranga Road and Tī Rākau Drive, especially during peak times to make travel easier. The project is a team effort involving Auckland Transport, Fletcher Construction, ACCIONA, AECOM, and Jacobs.

Our Brian Perry Civil Wellington team planted a variety of flaxes and other native plants along the Takapu Stream next to their Tawa Yard.

Our Brian Perry Civil Wellington team planted a variety of flaxes and other native plants along the Takapu Stream next to their Tawa Yard. Senior Environmental and Sustainability Advisor Julien Huteau organised the event on the eve of Matariki with the Porirua City Council who provided the plants and dug the holes. The planting will provide better flood protection and enhance the mana of the stream.

This Lunch and Learn session was presented by Michael Backhurst, Senior Sustainability Advisor at Kiwirail and Emma Foulkes, Senior Project Manager - Sustainable Outcomes at Height Project Management.

This Lunch and Learn session was presented by Michael Backhurst, Senior Sustainability Advisor at Kiwirail and Emma Foulkes, Senior Project Manager - Sustainable Outcomes at Height Project Management.

Michael has been at KiwiRail for one year and has been working on embedding sustainability across the wider KiwiRail Capital Works programme. He has a background in waste management, mainly in local government and was also involved with the first two Infrastructure Sustainability Council (ISC) ratings for the City Rail Link project.

Emma was a Project Engineer in Brian Perry Civil and completed a range of projects for us. She now works at Height Project management focusing on integrating sustainability practices in the construction industry.

Michael and Emma talked about some of the recent award winning work done for Kiwirail.

AI is rapidly showing its potential to uplift productivity across multiple industry sectors.

AI is rapidly showing its potential to uplift productivity across multiple industry sectors.

The AI Forum of New Zealand’s AI (Artificial Intelligence) Blueprint for Aotearoa New Zealand is intended to align with the New Zealand Government’s AI Principles and Roadmap and Callaghan Innovation’s work to encourage and support the adoption of AI in Aotearoa.

This paper presents a strategy to highlight current industry investments in AI in Aotearoa and help guide strategic investments over the next five years to support AI technologies. It proposes a mechanism to leverage existing industry initiatives and programmes to help drive results and achieve our shared vision.

Artificial Intelligence is rapidly showing its potential as a game-changing transformation tool across construction.

Artificial Intelligence is rapidly showing its potential as a game-changing transformation tool across construction. From revolutionising project management, improving safety outcomes, and optimising construction processes these technologies will be reshaping the future of our industry. This session was originally hosted by CCNZ Auckland Branch, and the webinar looks to share this important session with members nationally.

Hosted by CCNZ Technical Manager Michelle Farrell, CCNZ presented a panel of local experts for an introduction to this technology, providing advice on how to get started, and an open Q+A session.

In our special Lunch and Learn session, Andrew Williams and Caitlin Tonner from the Brisbane Stantec office give examples of how sustainability outcomes are driven and embedded into projects in their ...

In our special Lunch and Learn session, Andrew Williams and Caitlin Tonner from the Brisbane Stantec office give examples of how sustainability outcomes are driven and embedded into projects in their region. Andrew is a sustainability professional with 15 years of experience across many top tier engineering firms. Caitlin is a project technical lead with extensive infrastructure experience delivering ISC projects in Queensland.

Project Engineer Kyle Marshall explains how a bubble curtain has mitigated the environmental impact of marine piling at the Seaview Wharf project.

Project Engineer Kyle Marshall explains how a bubble curtain has mitigated the environmental impact of marine piling at the Seaview Wharf project. Kyle talks about how the team took an off the shelf product and came up with a number of innovative improvements to suit project requirements. This was originally a Design Community of Practise quickfire presentation.

Anglian Water is a world leader in reducing carbon emissions.

Anglian Water is a world leader in reducing carbon emissions. As an early starter, the big UK water utility embarked on its carbon zero journey in 2006 and is now on track to generate 45 percent of energy from its own renewable resources by 2025 and become a full net zero carbon business by 2030.

In this Spotify podcast Jon Reed and Hannah Edmond from the Water New Zealand climate change group talk to Anglian Water’s head of carbon neutrality, David Riley about the water utility’s bold approach to tackling climate change and the carbon reduction lens covering all aspects of its operation.

Click here to go to the podcast.

The City Rail Link (CRL) is being designed and constructed to the highest sustainability standards.

The City Rail Link (CRL) is being designed and constructed to the highest sustainability standards.

The CRL project aims to achieve sustainability excellence by being careful with the resources it uses, optimising its carbon footprint, avoiding waste and leaving a positive social and cultural legacy for Tāmaki Makaurau.

Visit the City Rail Link website

Nothing’s more important than keeping our people safe, but with a very diverse team, sometimes it's hard to know whether safety messages are being understood.

Nothing’s more important than keeping our people safe, but with a very diverse team, sometimes it's hard to know whether safety messages are being understood. That's why our EHS team is making safety videos available in multiple languages.

Learning Experience Designer Modi Chen produced the videos, and sourced translators from within the business. “As someone with English as a second language, I know that technical information like safety messages can be hard to understand. Working in EHS, it was really important to me to remove all barriers to understanding them.”

The first translated video, which features Puawai Waipouri, has Chinese, Hindi and Fijian subtitles, and Modi has plans to add more languages soon. You can watch the video here.

Brian Perry Civil's Seaview Wharf Resilience Project construction manager and environmental and sustainability advisor joined the Lunch and Learn session to talk about the ecological and environmental...

Brian Perry Civil's Seaview Wharf Resilience Project construction manager and environmental and sustainability advisor joined the Lunch and Learn session to talk about the ecological and environmental considerations working in Centre Point, Wellington.

What's next for you?

Join us and we’ll get you all set for what’s next – from the career you want to the lifestyle you’re dreaming of. The size and scale of our operations means we can offer an impressive range of opportunities across the country.