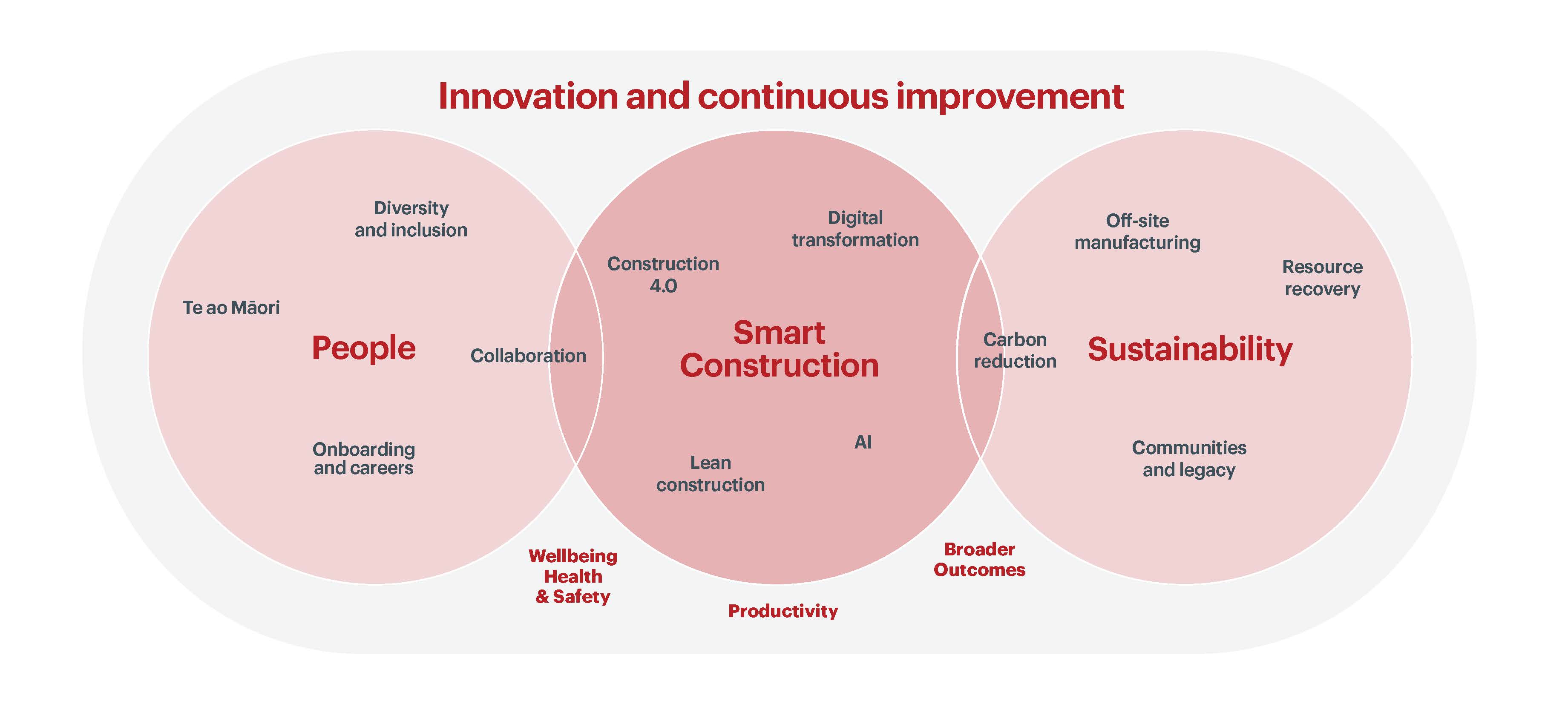

We take our role as a leader in the construction sector seriously.

We encourage our teams to use innovative approaches to solve issues and explore opportunities.

In the spirit of collaboration, we want to share this information with all construction professionals, experts, academia and thought leaders for the good of the wider industry.

We value the strength of collaboration and partnering in addressing the many interconnected opportunity areas for our sector.

To that end we want to promote and share the great work of partner organisations in these areas.

To view these stories, please share your details so we can send information that might be of interest and invite you to thought leadership events.

If you would like to learn more, or have information you’d like to share with the wider industry – contact the team here.

Liveable Streets South Rural, the team from Higgins and HEB who look after the roads in South Rural Auckland for Auckland Transport, is turning waste into opportunity.

Liveable Streets South Rural, the team from Higgins and HEB who look after the roads in South Rural Auckland for Auckland Transport, is turning waste into opportunity. In 2021, the team faced a challenge with discarded road edge marker posts (EMPs). By 2025, thanks to a partnership with WasteXpert and Plastics Recycling NZ (PRNZ), a joint venture between Waste Management New Zealand and Aliaxis New Zealand, over 1 tonne of EMPs have been diverted from landfill — nearly 100% of what was collected!

The team at Liveable Streets cleaned and sorted the EMPs, in bins provided by WasteXpert. These are then sorted into collection bins. The EMPs were soaked, cleaned, dried, and then transported to PRNZ for recycling. This initiative avoided 143 kg CO₂-e emissions and showcased how innovation can drive real environmental impact. The recycled material is now being repurposed into new products at Aliaxis facilities across New Zealand.

It's a great example of systems that work!

In this Lunch and Learn session, Project Engineer Kyle Marshall presents a detailed account of the Brian Perry Civil project's scope and innovative work methodologies implemented by the team to succes...

In this Lunch and Learn session, Project Engineer Kyle Marshall presents a detailed account of the Brian Perry Civil project's scope and innovative work methodologies implemented by the team to successfully deliver this challenging project for the Department of Conservation in Wellington Harbour.

This Coast and Ports Paper outlines the environmental and ecological strategies implemented during the Seaview Wharf piling project in Wellington, New Zealand, with a focus on protecting marine life a...

This Coast and Ports Paper outlines the environmental and ecological strategies implemented during the Seaview Wharf piling project in Wellington, New Zealand, with a focus on protecting marine life and the Waiwhetu Aquifer. It details the collaborative development of mitigation measures—such as acoustic monitoring and bubble curtains—to manage underwater noise and safeguard biodiversity during construction.

This report from Te Waihanga explores how New Zealand’s construction sector can improve project outcomes by adopting better contracting practices.

This report from Te Waihanga explores how New Zealand’s construction sector can improve project outcomes by adopting better contracting practices. Drawing on interviews with 26 industry participants, it highlights persistent issues with contract selection, working relationships, and dispute resolution—particularly around the widespread use and modification of NZS 3910. The findings offer practical insights and opportunities for more collaborative, transparent, and effective infrastructure delivery across the country.

This discussion paper from Te Waihanga outlines how New Zealand can improve infrastructure delivery by moving beyond traditional, lowest-cost procurement models.

This discussion paper from Te Waihanga outlines how New Zealand can improve infrastructure delivery by moving beyond traditional, lowest-cost procurement models. It introduces seven principles—ranging from systems thinking and digital transformation to integrated teams and value-based delivery—that help public sector clients become more sophisticated and outcomes-focused. The report draws on international best practices and local case studies to offer a roadmap for achieving better infrastructure results, greater efficiency, and long-term value.

This case study highlights the rapid reconstruction of the SH25A Taparahi Bridge in Coromandel following severe storm damage in early 2023.

This case study highlights the rapid reconstruction of the SH25A Taparahi Bridge in Coromandel following severe storm damage in early 2023. It showcases how emergency provisions, collaborative procurement, and accelerated delivery enabled the bridge to be completed in under 12 months—unlocking significant economic benefits for the region. The document offers valuable insights into fast-tracked infrastructure delivery and lessons for future resilience planning and project execution.

We invest in cutting-edge technology to ensure the health and safety of our workers.

We invest in cutting-edge technology to ensure the health and safety of our workers. We’ve introduced the use of the Hilti Nuron SensTech Grinder which offers a new level of safety for angle grinders. This grinder does not have a traditional mechanical deadman switch, a long-required safety feature. Instead, it features Hilti's SensTech system which uses touch-activated sensors and includes a 3D Active Torque Control (ATC) system.

The SensTech system is equipped with capacitive sensors that detect the user’s grip. If the sensors detect that the user's grip has moved or loosened, the system activates an auto-shutoff to prevent potential injuries. Additionally, the 3D ATC system senses if the grinder suddenly jerks in one direction or spins out, triggering the grinder to shut off before injury or damage can occur. This innovation enhances safety by replacing the mechanical deadman switch with a touch-activated system, without compromising the tool's performance.

Implementing this new grinder not only enhances safety on the job but also ensures compliance with updated safety standards.

The Eastern Busway project team faced a major challenge: how to streamline the construction of Rā Hihi, a 17- span public transit flyover in East Auckland.

The Eastern Busway project team faced a major challenge: how to streamline the construction of Rā Hihi, a 17- span public transit flyover in East Auckland. Traditional concrete monitoring methods were slowing them down.

The team turned to Converge and Canzac to track concrete curing and strength development in real time. With 34 bridge components requiring temperature monitoring, project engineers needed a reliable and user-friendly system to track concrete curing.

By using Converge sensors, the team safely accelerated their concrete cycle. This optimisation saved over a month on the project’s critical path, ensuring that construction remains ahead of schedule and is on track to be completed on time.

Reducing embodied carbon is a complex journey requiring collaboration and common understanding.

Reducing embodied carbon is a complex journey requiring collaboration and common understanding.

This 101 Guide from WaterNZ provides resources for Aotearoa practitioners in the water sector, and includes best practice case studies from Brian Perry Civil and Fletcher Living.

Click to view the document

The Brian Perry Civil Central Region team is constructing a piling platform for the BPC piling crew at the Te Maunga Bioreactor 2 ground improvement project.

The Brian Perry Civil Central Region team is constructing a piling platform for the BPC piling crew at the Te Maunga Bioreactor 2 ground improvement project. The selection of materials is crucial to ensure stability, cost- effectiveness, and environmental sustainability. Approximately 1800 tons of GAP65 will be required to construct the platform. This material is costly, considering the temporary nature of the platform, which must be removed upon the completion of the piling operation to allow for the installation of the topping concrete slab.

Crushed Concrete CC65 was proposed by the project team as a better alternative to construct the piling platform, providing several advantages:

Environmental Sustainability

- Recycling: Crushed concrete is a recycled material, which means it helps reduce the demand for virgin aggregates and minimises waste.

- Lower Carbon Footprint: Using recycled concrete reduces the carbon footprint associated with the extraction and processing of new materials.

- End-of-life scenarios: Can be reused for hardfill on other projects. Also, can be sent for recycling via quarry sites.

Cost-Effectiveness

- Lower Material Costs: Crushed concrete is often more affordable than GAP65 due to its recycled nature.

Ease of Construction

- Simple Installation: Crushed concrete is easy to install and compact, which can speed up the construction process.

- Versatility: It can be used in various construction applications, including sub-base layers and foundations.

In this lunch and learn session, Brian Perry Civil's Senior Project Manager Phil Wild and Senior Project Engineer Pavan Satish share the project team's key lessons from the large-scale infrastructure ...

In this lunch and learn session, Brian Perry Civil's Senior Project Manager Phil Wild and Senior Project Engineer Pavan Satish share the project team's key lessons from the large-scale infrastructure upgrade of the Whenuapai Airbase.

BPC Site Superintendent Paddy Molloy recognised an opportunity to improve environmental practices by avoiding used safety glasses being sent to landfill.

BPC Site Superintendent Paddy Molloy recognised an opportunity to improve environmental practices by avoiding used safety glasses being sent to landfill.

Working with Project Administrator Sue Hodder at their Seaview Wharf site, they’re now ensuring an average of 70 pairs of glasses are being recycled each month.

They’re working with Terracycle, a company offering a range of recycling options for construction site waste. The next objective is to introduce recycling boxes for gloves and other personal protective items.

While it can be tempting to ‘ease’ into things at the start of the year, it is integral we hit the ground running with our safety mindset fully engaged so none of our people become one of the 'lucky o...

While it can be tempting to ‘ease’ into things at the start of the year, it is integral we hit the ground running with our safety mindset fully engaged so none of our people become one of the 'lucky ones'.

In this powerful story, hear from Brian Perry Civil's Mason Hohepa, in the Bay of Plenty, who shares his close call with a serious injury, and the valuable lessons he and his team learned about staying committed to safety-on-site.

Everyday, we live our values to care for each other, so we can all call go home safely and through our dedicated safety culture programme Protect, we have built a strong collective belief that all injuries are preventable.

Our Higgins Traffic team is leading a recycling initiative aimed at boosting sustainability and reducing costs.

Our Higgins Traffic team is leading a recycling initiative aimed at boosting sustainability and reducing costs.

The team, which relies heavily on traffic management, previously faced high expenses for aluminium traffic signs. Old and damaged signs were sent to scrap metal, yielding less than one-eighth of their original cost. Traffic Operations Manager Sanjesh Narayan reviewed the current process and explored the feasibility of reusing or refurbishing these signs. The findings revealed that recycling the signs was far more cost-effective than purchasing new ones.

This initiative resulted in significant savings for the division. Large signs were converted into multiple smaller ones at half the original cost, reducing expenses and increasing the inventory of usable signs. This recycling effort has made their operations more sustainable by reusing materials and cutting down on costs.

Safety is a core value and a core part of who we are.

Safety is a core value and a core part of who we are. We want to help create safer workplaces for everyone, everywhere. That’s why we’re sharing our safety journey online through a new safety section on the Fletcher Building website.

By openly sharing our learnings, progress, approach, and commitment, we’re working to ensure that everyone goes home safe, every day and contributing to a stronger safety culture across the industries and communities we work in.

We’d love to hear from others in the EHS space—how is your business driving safety excellence? Let’s keep the safety conversation going.

Click here to visit the page.

The Eighteenth East Asia-Pacific Conference on Structural Engineering and Construction (EASEC-18) was held on 13–15 November 2024 at the Shangri-La Chiang Mai in Thailand.

The Eighteenth East Asia-Pacific Conference on Structural Engineering and Construction (EASEC-18) was held on 13–15 November 2024 at the Shangri-La Chiang Mai in Thailand. The conference was hosted by the School of Civil Engineering and Technology, Sirindhorn International Institute of Technology, Thammasat University.

Fletcher Higgins Fiji Project Manager Tiago Ribeiro presented two technical papers - Bulu Bridge – Repairs and Overlay with Latex Modified Concrete Reinforced with Fibres, and Wainawi Bridge – 2 Stage Construction Methodology.

Facing the climate challenge demands leadership and collaboration across the entire industry.

Facing the climate challenge demands leadership and collaboration across the entire industry. At the recent Carbon Crunch event hosted by Mott MacDonald, Brian Perry Civil Environmental and Sustainability Manager Rachel Blake represented the construction sector, highlighting the tailwinds and crosswinds in the journey towards decarbonization. It was an informative and thought-provoking event that delved into the path forward and the crucial imperatives we must address together to eliminate carbon from our future.

Due to a lack in historical evidence and as-built records, service investigation is becoming increasingly more important.

Due to a lack in historical evidence and as-built records, service investigation is becoming increasingly more important.

Locating services during planning processes for projects can stop service strikes, costly conflicts, redesigns and unsafe environments for our workers, including in some cases loss of life.

In this Lunch and Learn session, Geospatial Technician Briana Stemp talks about GPR benefits and service locating processes.

What's next for you?

Join us and we’ll get you all set for what’s next – from the career you want to the lifestyle you’re dreaming of. The size and scale of our operations means we can offer an impressive range of opportunities across the country.